Top 10 Industrial Fans and Blowers for Efficient Ventilation?

Efficient ventilation is essential in various industries. The role of Industrial Fans And Blowers cannot be overstated. According to a report by the Instituto Nacional de Estadística y Geografía, the industrial fan market is projected to grow at 4.5% annually. This highlights the ongoing demand for effective air movement solutions.

Industry expert Dr. James Holloway states, "Choosing the right Industrial Fans And Blowers is critical for operational efficiency." His insights echo the need for precision in selecting tools that align with specific ventilation requirements. The challenge remains; many facilities overlook the intricacies of these systems. Ignoring the proper specifications can lead to inefficiencies and increased costs.

The landscape of Industrial Fans And Blowers continues to evolve. Emerging technologies offer better energy efficiency and quieter operation. However, the quest for optimal performance often requires continuous evaluation. As we explore the top industrial fans and blowers, it's vital to reflect on why proper selection and maintenance are crucial. The consequences of negligence can be costly, both environmentally and economically.

Understanding Industrial Fans and Blowers: An Overview

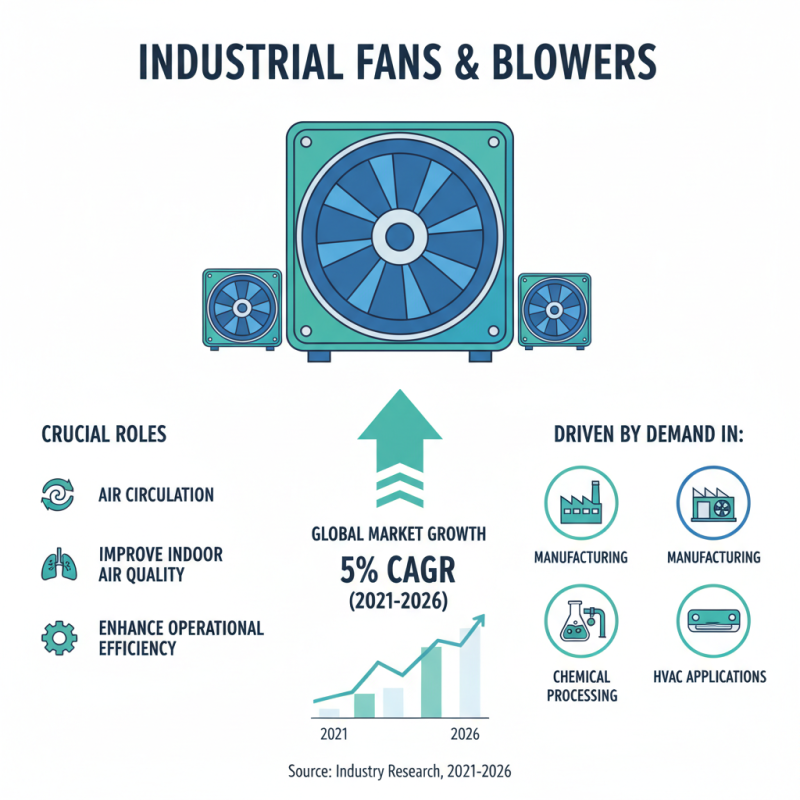

Industrial fans and blowers play a crucial role in various sectors. They ensure proper air circulation, improving indoor air quality and operational efficiency. According to recent industry research, the global industrial fan market is projected to grow at a CAGR of 5% from 2021 to 2026. This growth is driven by increasing demand in sectors like manufacturing, chemical processing, and HVAC applications.

Understanding the different types of industrial fans and blowers is essential. Axial fans provide high airflow at low pressure. They are commonly used for cooling and ventilation. Centrifugal fans, on the other hand, deliver higher pressures and are more efficient in moving air through duct systems. A miscalculation in fan selection can lead to energy waste and reduced effectiveness. Reports indicate that improperly sized fans can result in a 30% increase in energy consumption. It's a problem that shouldn't be overlooked.

Maintenance is another critical aspect. Regular checks can prevent unexpected breakdowns. Over 40% of industrial facilities report efficiency losses due to fan maintenance issues. Simple tasks, like cleaning and lubrication, can make a significant difference. Neglecting these can lead to performance drops and unexpected costs. Recognizing these challenges is the first step toward improvement.

Key Features to Consider When Choosing Industrial Fans

When selecting industrial fans, key features are crucial. Consider airflow capacity. It determines how much air the fan can move per minute. This is vital for effective ventilation. Look for fans that can handle your space requirements. Assess the noise level, too. Some fans can be excessively loud, impacting work environments. A quieter option may be preferable, especially in sensitive areas.

Next, think about the fan’s energy efficiency. An efficient fan will save you money on energy bills. Check the motor type; a high-efficiency motor pays off in the long run. Also, consider the build material. Durable materials resist corrosion and last longer. This can reduce maintenance costs. Don't forget about the installation process. Some fans require professional setup, which adds to costs.

Finally, think about the control options. Adjustable speed settings provide flexibility. Automatic sensors can optimize performance based on conditions, enhancing efficiency. Yet, this means more complexity in operation. Carefully weigh the benefits against potential difficulties. Choosing the right industrial fan involves multiple considerations. Each choice impacts performance and operating costs.

Top 10 Industrial Fans and Blowers for Efficient Ventilation

| Model | Type | Airflow (CFM) | Power Consumption (W) | Noise Level (dB) | Special Features |

|---|---|---|---|---|---|

| Model A | Axial Fan | 1500 | 200 | 70 | Corrosion-resistant |

| Model B | Centrifugal Fan | 2000 | 250 | 65 | High efficiency |

| Model C | Blower | 1800 | 300 | 75 | Variable speed |

| Model D | Axial Fan | 1600 | 220 | 68 | Lightweight design |

| Model E | Centrifugal Fan | 2100 | 260 | 72 | Compact size |

| Model F | Blower | 1750 | 280 | 74 | Durable construction |

| Model G | Axial Fan | 1900 | 240 | 67 | High airflow |

| Model H | Centrifugal Fan | 2200 | 300 | 71 | Energy-efficient |

| Model I | Blower | 2000 | 290 | 73 | Low maintenance |

| Model J | Axial Fan | 2300 | 310 | 69 | Multi-speed operation |

Top Industrial Fan Types and Their Applications

Industrial fans and blowers are essential for various applications across sectors. They ensure proper ventilation, cooling, and air circulation. Different types serve distinct needs. For example, axial fans excel in high-flow, low-pressure situations. They are commonly found in factories and warehouses. Their design permits large volumes of air movement, but they may struggle with high resistance environments.

Centrifugal fans, on the other hand, generate higher pressure. They are suitable for situations where air needs to be moved through ducts. These fans work effectively in HVAC systems and cleanroom environments. Their construction is more complex, which might lead to increased maintenance needs. Proper selection is crucial to avoid inefficiencies and increased operational costs. Striking the right balance between air volume and pressure can be challenging.

Additionally, vane-axial fans provide flexibility by combining features of both types. They are widely used in industrial applications. Concerns about energy efficiency often arise. Choosing the right fan type can lead to significant energy savings. However, understanding the operational requirements may take time and effort. Each type has its own advantages, yet mistakes in selection can hinder performance.

Efficiency Ratings and Energy Consumption for Ventilation Solutions

When selecting industrial fans and blowers, efficiency ratings matter significantly. These ratings determine how much airflow is generated per unit of energy consumed. Higher ratings indicate better performance, leading to reduced energy costs. Typically, the best models use advanced motor technology. This can minimize electricity use while maximizing airflow.

Energy consumption is another crucial factor. Fans and blowers have different operating conditions. Some work best in low-speed applications, while others excel at high speeds. Understanding your specific needs helps in choosing the right equipment. For instance, a fan running constantly at high speeds may waste energy in a facility with fluctuating ventilation requirements. Regular maintenance is also key. Dirty filters can increase energy consumption considerably.

Reflecting on choices made can lead to better decisions. Are you focusing only on initial costs? This might overlook long-term efficiency savings. Assessing the energy impact of different models often reveals unexpected insights. Making thoughtful selections enhances overall ventilation effectiveness. It is more than just picking the most powerful unit; it’s about the balance between performance and energy use.

Leading Brands in the Industrial Fan and Blower Market

In the industrial sector, ventilation is critical. Efficient fans and blowers are essential for moving air and maintaining air quality. Choosing the right brand can greatly impact performance. Many leading brands focus on technology and durability. They offer various options for different needs, including specific airflow patterns and energy efficiency.

Tips for selection: Consider the size of your space. A larger space requires more powerful fans. Look for adjustable speed settings. This feature allows for customized airflow. Don't overlook noise levels; some models are quieter than others. It’s important to find a balance between efficiency and comfort.

Pay attention to maintenance requirements as well. Some fans and blowers need more care. Regular cleaning can prolong their life. Monitor for vibrations during operation; they can indicate problems. Reflecting on these details can guide your purchase. Investing wisely will enhance work environments.

Related Posts

-

7 Essential Tips for Maximizing Efficiency with Industrial Centrifugal Fans in Your Facility

-

The Future of Efficient Dust Control with Advanced Bag House Systems

-

Ultimate Guide to Choosing the Right Dust Collector Filter Bags for Your Industry Needs

-

Maximize Durability with 5 Essential Tips for Cost Effective Maintenance of Best Industrial Blowers

-

Unlocking Global Trade Opportunities with Sawdust Vacuum System at the Canton Fair 2025

-

7 Reasons Why the Best Sawdust Collector is Essential for Your Workshop