Rubber Pump Impeller Tips for Optimal Performance and Selection?

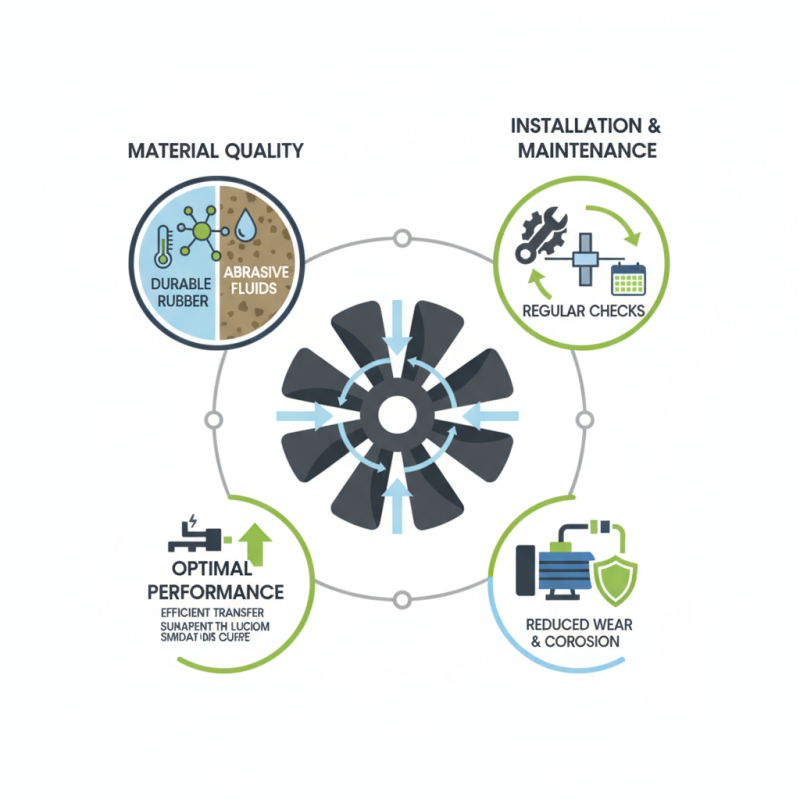

When selecting a Rubber Pump Impeller, performance is crucial. The right choice ensures efficient fluid transfer and reduces wear. Impellers made from rubber are known for their flexibility and resistance to corrosion. They are ideal for various applications, including those involving abrasive fluids.

However, many overlook the importance of material quality. Not all rubber types offer the same durability or performance. Identifying the right rubber grade can be challenging. Factors like temperature and fluid type play significant roles in this process.

Additionally, installation practices are often ignored. Improper alignment can lead to failure, despite having a high-quality Rubber Pump Impeller. Regular maintenance checks are essential too. Neglecting these can cause the system to underperform over time. Therefore, understanding these factors is crucial for optimal performance and longevity.

Understanding Rubber Pump Impellers: Functions and Applications

Rubber pump impellers play a vital role in various applications. They are essential for moving fluids efficiently. Impellers create centrifugal force, pushing the fluid outward. This action creates pressure, allowing fluid to flow through a system. They work well in many settings, from industrial to agricultural.

In many cases, users overlook the importance of material selection. Rubber offers flexibility and resistance to wear. However, not all rubber is the same. Variations exist among types of rubber, each suited for different conditions. Understanding these differences can enhance performance. Using inappropriate materials can lead to failures and increased costs. Ideal scenarios require careful consideration of the environment where the pump operates.

Maintenance is another critical aspect. Regular inspection can prevent unexpected issues. Impellers may degrade over time, affecting efficiency. Users must remain vigilant. Neglect can lead to significant downtime. Not addressing wear and tear can compromise the entire system. Being proactive can ensure smooth and reliable operation.

Rubber Pump Impeller Tips for Optimal Performance and Selection

| Dimension | Description | Application | Material Type | Optimal RPM |

|---|---|---|---|---|

| 4 inches | Standard impeller for general-purpose applications. | Water treatment, irrigation | Nitrile Rubber | 1800 - 3600 RPM |

| 6 inches | High-efficiency impeller for larger flows. | Industrial drainage, wastewater | EPDM Rubber | 1500 - 3000 RPM |

| 8 inches | Heavy-duty impeller suitable for aggressive fluids. | Chemical processing | Hypalon Rubber | 1200 - 2400 RPM |

Factors Influencing the Performance of Rubber Pump Impellers

When selecting rubber pump impellers, several factors play a crucial role in performance. The material composition is essential. High-quality rubber offers flexibility and durability. According to a recent industry report, using advanced rubber compounds can increase the impeller life by up to 20%. Knowing the specific application helps in choosing the right hardness. Softer rubber may be better for delicate fluids, while harder compounds work for abrasive materials.

Another critical factor is the impeller design. Different geometries affect flow rates and efficiency. A study indicates that optimizing the blade shape can enhance pump efficiency by as much as 15%. Regular maintenance is vital, too. Impellers should be inspected for wear and tear. Even a small defect can lead to significant performance drops.

Tips: Always check compatibility with fluid properties. Consider temperature and chemical resistance. Look for signs of degradation after prolonged use. These factors can jeopardize optimal performance. Testing under realistic conditions can reveal more about reliability. Ensuring your impeller matches the system demands is often overlooked, but it's crucial for sustained operation.

Criteria for Selecting the Right Rubber Pump Impeller

Choosing the right rubber pump impeller is crucial for optimal performance. Several factors come into play, including material, design, and application. Industry studies show that incorrect selection can lead to a significant reduction in efficiency, sometimes up to 30%. Therefore, understanding these criteria can make a notable difference.

Material selection is paramount. Rubber impellers come in various compounds, each suited for different applications. For example, natural rubber offers great flexibility and resilience but may not withstand harsh chemicals. In contrast, synthetic rubber compounds often have enhanced resistance. The environmental conditions of the pump's operation should guide your choice. For instance, high temperatures require specialized rubber with specific thermal properties.

Tip: Always consider the pump's operating conditions. High flow rates can stress the impeller, leading to failures. A well-balanced impeller design reduces wear and extends longevity. Moreover, testing under real operational conditions can help identify shortcomings. It’s essential to regularly reevaluate the chosen impeller as the working environment changes. Understanding your needs is key to achieving the best results. Regular performance assessments can provide insights into the effectiveness of the chosen impeller.

Maintenance Tips for Extending the Lifespan of Rubber Impellers

Rubber impellers are crucial for efficient pump performance. However, they often endure significant wear and tear. A recent industry report stated that nearly 30% of impeller failures are due to improper maintenance. Regular inspections can help address potential issues before they escalate.

To extend the lifespan of rubber impellers, implement a routine maintenance schedule. Regular cleaning can prevent debris buildup. Buildup not only affects efficiency but may also lead to mechanical damage. Check for signs of wear, such as cracks or warping. These problems can affect performance and increase energy consumption.

Temperature also plays a vital role in the lifespan of rubber impellers. Reports indicate that operating above recommended temperatures can reduce rubber strength by 20%. Consider using temperature gauges to monitor conditions. Also, ensure proper lubrication; inadequate lubrication can lead to increased friction and quick wear. Understanding these factors is key to maintaining optimal performance.

Common Issues and Troubleshooting for Rubber Pump Impellers

Rubber pump impellers are critical components in various industrial applications. However, they can encounter several common issues. One major problem is cavitation, which often occurs due to low operational pressure. According to a study by the Hydraulic Institute, cavitation can reduce the impeller's efficiency by up to 30%. Once initiated, it can cause damage that impacts long-term performance.

Another issue is wear and tear from abrasives in the fluid. Over time, rubber impellers may lose their shape, leading to reduced flow rates. Data from the American Society of Mechanical Engineers suggests that improper selection of materials can reduce service life by 50%. Regular inspections are essential to catch these problems early. Look for signs of surface degradation, which can indicate deeper issues.

Temperature fluctuations can also affect performance. A 2020 report from the International Pumps Association highlighted that operating beyond recommended temperature ranges could lead to premature failure. It's crucial to monitor the working environment and adjust pump operations accordingly. Addressing these challenges requires diligence and a proactive approach to maintenance. Ignoring signs of wear can lead to unexpected downtime and costly repairs.