What is an Injection Machine Robot and How Does it Work?

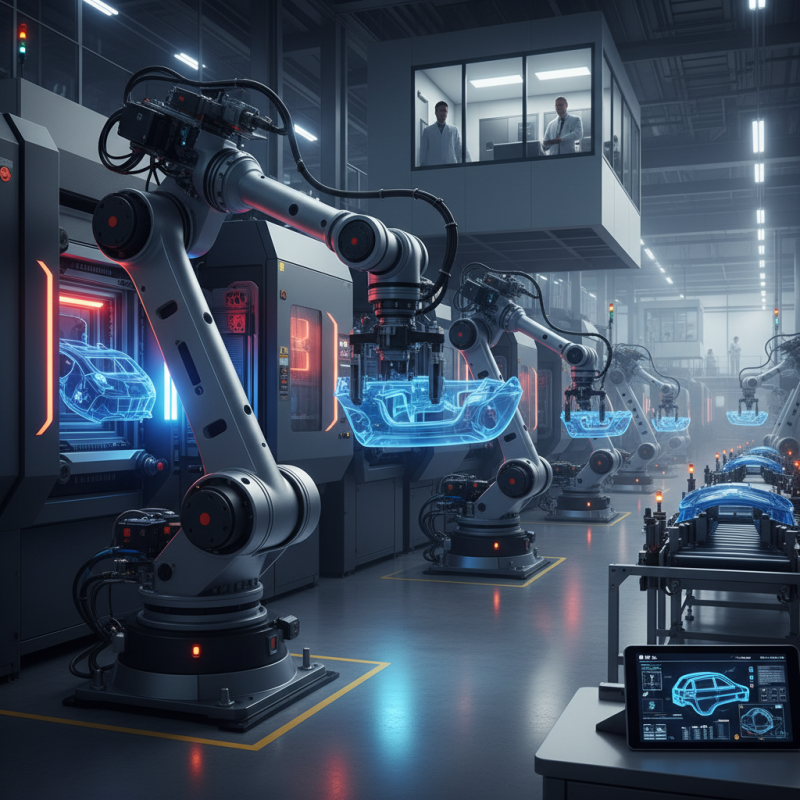

In today’s manufacturing world, the use of an Injection Machine Robot is critical. These robots automate the injection molding process, increasing efficiency and precision. John Smith, a renowned expert in robotics, states, “Injection Machine Robots transform the way we produce complex parts.” His words highlight the importance of this technology.

Injection Machine Robots streamline production lines. They reduce human error and improve speed. Yet, these machines are not perfect. Programming errors or mechanical malfunctions can occur. Companies must invest in training and regular maintenance to minimize these risks. The reliance on technology can lead to challenges that require ongoing reflection and adjustment.

As industries lean into automation, understanding Injection Machine Robots becomes vital. These robots are shaping the future of manufacturing, but businesses must balance technology with human oversight. Embracing this innovation involves facing both its advantages and its potential drawbacks.

What is an Injection Machine Robot?

An injection machine robot is a specialized device designed for automating the process of injection molding. This technology is pivotal in the manufacturing of plastic parts. The robot operates by introducing molten plastic into a mold, where it cools and solidifies into the desired shape.

The system typically includes a hopper for feeding plastic pellets. Once heated, the plastic transforms into a liquid form. The robot then injects this liquid into steel molds under high pressure. Precision is crucial here. Any inconsistency can lead to defects in the finished product. Operators often encounter challenges in achieving the perfect balance of pressure and temperature. This can require adjustments and close monitoring.

While the efficiency of an injection machine robot is remarkable, it’s not without its flaws. For instance, if the mold isn't aligned correctly, it can result in quality issues. Over time, wear and tear can also affect performance. Regular maintenance is vital to keep the machine running smoothly. Despite its advantages, users must remain vigilant about these aspects.

Key Components of Injection Machine Robots

Injection machine robots are intricate systems designed for the plastic molding industry. They streamline the process by automating various tasks. Understanding their key components is essential for effective operation.

One major component is the injection unit. It melts plastic granules and injects them into molds. The precision of this unit affects the final product's quality. Another crucial part is the clamping unit, which holds molds together during injection. A strong clamp ensures no material leaks occur.

**Tips:** Regular maintenance on these units can avoid costly downtime. Additionally, always check for wear in components. This can prevent unexpected failures.

The control system is equally important. It dictates the machine's operations and parameters. A poorly programmed control system can lead to inconsistent product outputs. Lastly, the robot arm is essential for transferring materials and finished products. However, if calibrated incorrectly, it might mishandle parts. Attention to detail in these components can improve performance.

What is an Injection Machine Robot and How Does it Work? - Key Components of Injection Machine Robots

| Component | Description | Function | Importance |

|---|---|---|---|

| Robot Arm | The manipulator that moves and positions mold components. | Enables precision handling of components during injection molding. | Critical for maintaining accuracy in positioning. |

| End Effector | The tool at the end of the robot arm used for gripping and manipulating molds. | Facilitates the loading and unloading of parts. | Essential for effective part handling. |

| Control System | The brain of the robot, managing movements and operations. | Coordinates robot actions based on programmed instructions. | Vital for automation and efficiency. |

| Sensors | Devices that provide feedback and monitoring of robot operations. | Enhance the precision and safety of the robot's movements. | Crucial for ensuring operation reliability. |

| Power Supply | Supplies power to all electronic components and motors. | Essential for the robot's functionality. | Fundamental for operation. |

How Injection Machine Robots Operate: A Step-by-Step Guide

Injection machine robots play a crucial role in modern manufacturing. They automate the plastic injection molding process, enhancing efficiency and precision. Understanding how these robots operate is essential for industries relying on mass production.

The process begins with the robot positioning itself over the injection machine. It waits for the operator's command. Once activated, the robot picks up a mold and places it in position. Sensors ensure the mold is aligned correctly. This initial setup is critical; any misalignment can lead to defects. The robot then opens the injection machine, allowing molten plastic to flow into the mold.

After the plastic cools, the robot retrieves the finished product. This step involves precision and speed, minimizing the risk of damage. Industry reports indicate that automating this task can improve production rates by up to 30%. However, not all operations are perfect. Depending on the complexity of the mold, occasional errors may occur. Regular maintenance can help reduce such issues.

**Tips:** Ensure regular calibration of the robot to maintain accuracy. Training staff to troubleshoot basic errors can save time and reduce downtime. Monitor production data to identify any recurring problems.

Applications of Injection Machine Robots in Various Industries

Injection machine robots play a vital role in numerous industries. They automate the injection molding process, enhancing production efficiency and quality. In the automotive sector, these robots produce components like dashboards and bumpers. They provide precision and repeatability, which minimizes waste.

In the consumer goods industry, injection machine robots create everyday items. Toys, packaging, and household tools are often made using this technology. These robots reduce labor costs and ensure uniformity in products. However, not all industries fully embrace this automation yet. Some small manufacturers still rely on manual processes.

Despite their benefits, challenges exist. Integrating robots into existing systems can be complex. Workers may need retraining to operate new machinery. The upfront cost of robotics may deter some businesses. A balance between automation and human labor is essential for future growth.

Future Trends in Injection Machine Robot Technology

The future of injection machine robot technology looks promising. These machines are becoming more intelligent with advancements in artificial intelligence and machine learning. Smart sensors improve efficiency and accuracy during production. They can detect defects in real-time, reducing waste and saving costs.

However, challenges remain. Integrating AI into existing systems is not straightforward. Some machines still require manual adjustments. This can lead to production inconsistencies. Many manufacturers are exploring hybrid solutions to balance automation and human oversight.

Sustainability is another vital trend. Companies are seeking eco-friendly materials and processes. More robots will use renewable energy sources. This shift could lead to a significant decrease in carbon footprints. As technology evolves, the industry must adapt and innovate. The goal is to create robust systems that benefit everyone involved.