5 Essential Tips for Choosing the Best Industrial Centrifugal Fan

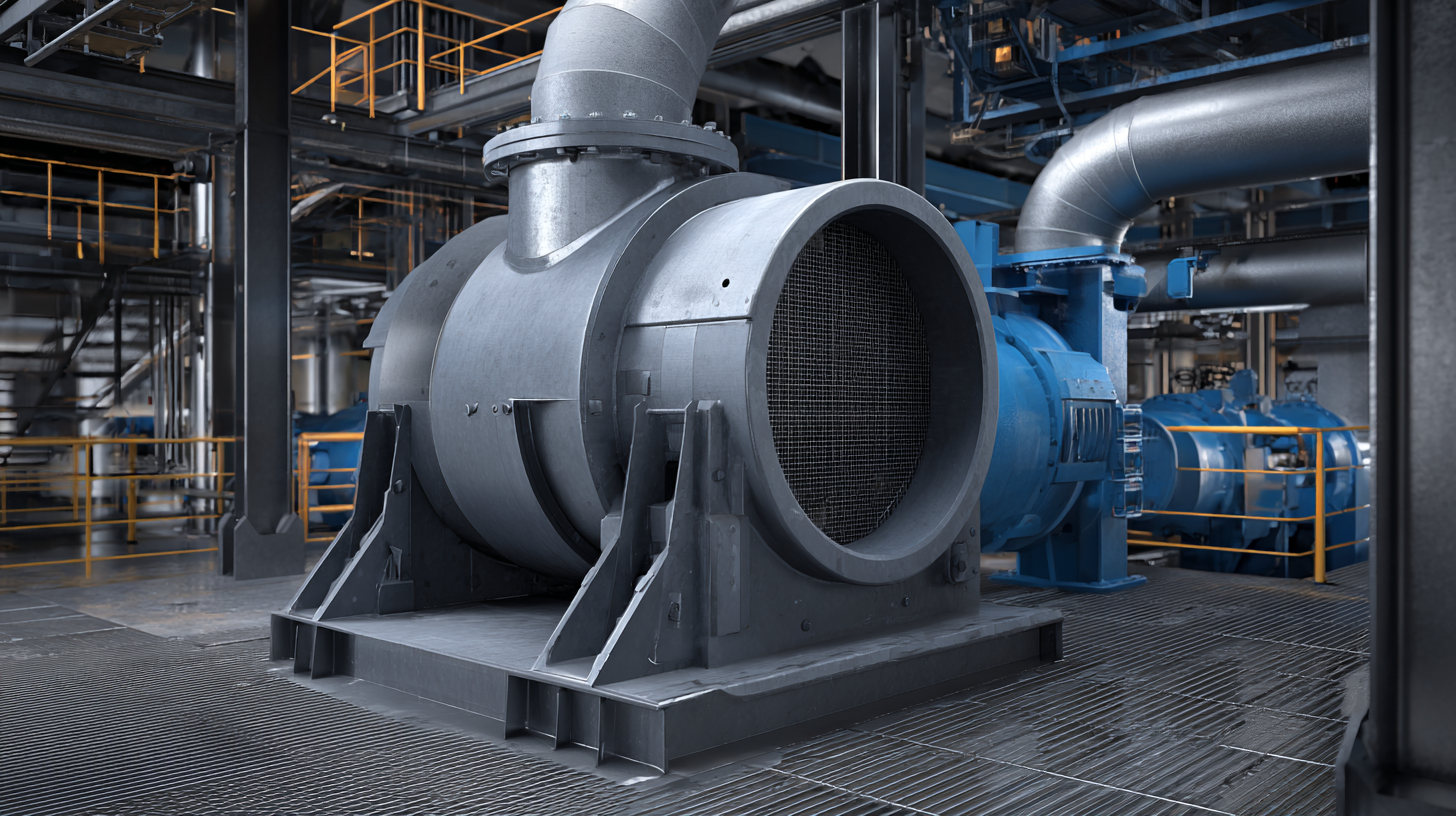

In today's fast-paced industrial environment, the selection of the right equipment is crucial for optimizing operational efficiency and ensuring consistent performance. Among the essential components in various manufacturing processes, the Industrial Centrifugal Fan plays a pivotal role in air movement and dust control. According to a recent market research report by Global Industry Analysts, the global industrial fan market is projected to reach $12.3 billion by 2026, driven by the increasing demand for energy-efficient solutions and stringent environmental regulations. Choosing the best Industrial Centrifugal Fan can directly impact production outcomes, energy consumption, and maintenance costs. With the complexities involved in this selection process, it is imperative for industries to understand the benefits and operational requirements associated with different fan types, ensuring they make informed decisions that align with their specific needs and operational goals.

Benefits of Robust After-Sales Service in Industrial Centrifugal Fans

When selecting industrial centrifugal fans, the importance of robust after-sales service cannot be overstated. A reliable after-sales support system ensures not only the longevity of the equipment but also enhances operational efficiency. According to industry reports, businesses that leverage strong after-sales service experience up to 20% fewer equipment-related issues, leading to significant cost savings on maintenance and repairs over time.

When selecting industrial centrifugal fans, the importance of robust after-sales service cannot be overstated. A reliable after-sales support system ensures not only the longevity of the equipment but also enhances operational efficiency. According to industry reports, businesses that leverage strong after-sales service experience up to 20% fewer equipment-related issues, leading to significant cost savings on maintenance and repairs over time.

Additionally, the performance of industrial centrifugal fans directly impacts energy consumption. High-efficiency fans can reduce energy usage by approximately 30%, which aligns with the growing trend of sustainability in industrial applications. The recent installation of large-capacity chillers in Singapore’s Marina Bay District Cooling System, designed with low environmental impact, underscores the need for efficient equipment that can handle large volumes while minimizing resource expenditure. Such advancements exemplify how effective after-sales service contributes to the proper installation and maintenance of high-efficiency fans, ensuring they deliver optimal performance throughout their lifecycle.

Cost Implications of Maintenance: Analyzing Repair Expenses Over Time

When selecting an industrial centrifugal fan, one key aspect to consider is the cost implications of maintenance, specifically how repair expenses accumulate over time. While the initial investment in a high-quality fan might be higher, the long-term savings can be significant when you factor in reliability and reduced maintenance needs. Inferior fans often lead to frequent breakdowns, resulting in increased costs associated with repairs and downtime. By opting for a robust design and superior materials, facilities can mitigate these recurring expenses, ultimately benefiting their operational budget.

When selecting an industrial centrifugal fan, one key aspect to consider is the cost implications of maintenance, specifically how repair expenses accumulate over time. While the initial investment in a high-quality fan might be higher, the long-term savings can be significant when you factor in reliability and reduced maintenance needs. Inferior fans often lead to frequent breakdowns, resulting in increased costs associated with repairs and downtime. By opting for a robust design and superior materials, facilities can mitigate these recurring expenses, ultimately benefiting their operational budget.

Furthermore, predictive maintenance and proper monitoring can greatly extend the lifespan of a centrifugal fan, thereby decreasing repair expenses over time. Implementing regular maintenance schedules and leveraging technology to predict potential failures can help identify issues before they escalate, saving facilities both time and money. Moreover, understanding the total cost of ownership, which includes purchase price, maintenance, and operational costs, is crucial in making an informed decision. Ultimately, a well-chosen centrifugal fan not only ensures efficient operation but also minimizes long-term maintenance costs, leading to a more sustainable and economically viable solution.

Real-World Examples: Successful After-Sales Support Cases in the Industry

When selecting an industrial centrifugal fan, the importance of after-sales support cannot be overstated. A reliable after-sales service can significantly enhance the performance and lifespan of the equipment. For instance, consider a manufacturing facility that invested in high-capacity centrifugal fans for its production line. The initial installation encountered vibrations due to misalignment, but the prompt response from the manufacturer's support team not only addressed the issue swiftly but also provided ongoing monitoring to prevent future problems. This proactive approach not only saved time but also ensured the fan operated efficiently, maximizing productivity.

Another compelling example is from a chemical processing plant that faced challenges with airflow consistency. After purchasing a new centrifugal fan, they experienced operational hiccups. The company’s after-sales support team not only helped troubleshoot the airflow issues but also implemented a customized maintenance plan based on the plant's specific needs. This collaboration resulted in improved performance and reliability, showcasing how effective support can transform an initial challenge into a successful operation.

These real-world cases highlight that investing in a centrifugal fan is not just about selecting the right equipment but also about the assurance of robust after-sales support. It provides manufacturers with peace of mind, knowing they have access to expertise that can solve problems quickly and effectively, leading to sustained operational success.

Performance Comparison of Different Industrial Centrifugal Fans

Impact of After-Sales Service on Operational Efficiency in Manufacturing Sectors

When selecting an industrial centrifugal fan, the impact of after-sales service can significantly influence operational efficiency in the manufacturing sector. After all, the proper functioning of these fans is crucial to maintaining production flow and ensuring the quality of the end product. A fan that operates irregularly or fails to perform at optimal levels can lead to downtime, increased energy costs, and potential damage to machinery or materials. Therefore, having robust after-sales support is essential for troubleshooting and maintaining fan performance.

Moreover, after-sales services like regular maintenance checks and prompt repairs are invaluable in extending the lifespan of centrifugal fans. Manufacturers that offer comprehensive service packages can quickly address any operational issues, which minimizes disruptions in production lines. This proactive approach not only enhances equipment efficiency but also cultivates trust between the supplier and the manufacturer, ultimately contributing to a more productive and harmonious working environment. Thus, when choosing an industrial centrifugal fan, potential buyers should prioritize suppliers known for their exceptional after-sales service, as it can have a lasting impact on operational efficiency.

Understanding Warranty Policies: Key Factors to Consider When Choosing Fans

When selecting industrial centrifugal fans, understanding warranty policies is a crucial factor that can significantly impact long-term satisfaction and financial planning. A solid warranty can provide peace of mind, ensuring that repairs or replacements are covered should any issues arise. Look closely at the duration of the warranty and what specific components are included. A comprehensive warranty will typically cover not just the fan's motor but also any other vital internal components that may be prone to wear and tear.

Additionally, consider the warranty service process. How easy is it to file a claim? What is the expected response time? Some manufacturers may offer extensive coverage but lack the customer service to back it up, leaving you in a lurch when problems occur. Reading customer reviews can offer valuable insights into the claims process and overall satisfaction with warranty services. By prioritizing these warranty considerations, you can make a more informed decision that enhances the reliability and efficiency of your industrial operations.