5 Compelling Reasons Why the Best Magnetic Drum Separator is Essential for Your Business

In today's competitive industrial landscape, enhancing efficiency and ensuring product quality are paramount for any business. One essential tool that is often overlooked yet proves to be invaluable is the Magnetic Drum Separator. This powerful equipment plays a crucial role in the separation of ferrous materials from non-ferrous materials, thereby streamlining production processes and reducing downtime caused by equipment wear. As companies strive to uphold stringent quality standards and optimize their operational workflows, understanding the compelling reasons behind investing in the best Magnetic Drum Separator becomes vital. In this blog, we delve into five key benefits that highlight why this innovative technology is not just an option, but a necessity for businesses aiming for excellence in their respective industries.

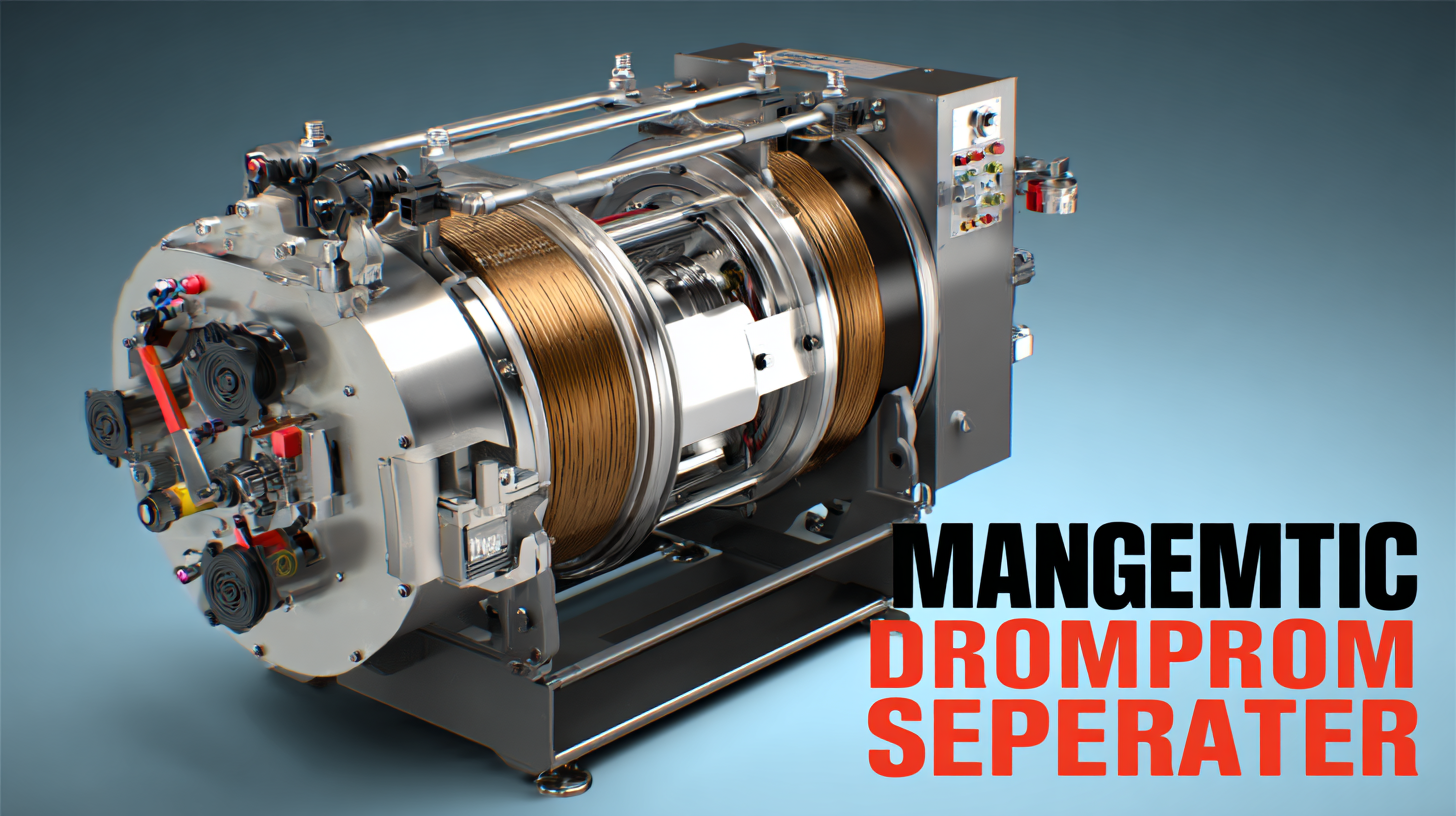

The Role of Magnetic Drum Separators in Enhancing Operational Efficiency

Magnetic drum separators play a crucial role in enhancing operational efficiency across various industries. By effectively removing ferrous contaminants from bulk materials, these separators ensure that the final product maintains the highest quality. This not only reduces the risk of equipment wear and tear but also minimizes the potential for expensive downtimes. A well-functioning magnetic drum separator can streamline processes, allowing businesses to maintain a steady workflow and increase throughput.

Furthermore, the integration of magnetic drum separators in the production line leads to significant cost savings over time. By eliminating unwanted metal particles, companies can prevent contamination that could compromise product integrity, thereby safeguarding their reputation and customer trust. Beyond operational efficiencies, these separators also contribute to workplace safety by reducing hazards associated with metal debris, ensuring a more secure environment for employees. The role of magnetic drum separators, therefore, extends beyond mere filtration—it is about optimizing performance and fostering sustainable practices in the manufacturing process.

How Magnetic Drum Separators Mitigate Contamination Issues

Magnetic drum separators are pivotal in maintaining the quality and integrity of products in various industries by effectively mitigating contamination issues. These devices use powerful magnets to attract and separate ferrous materials from non-magnetic particles during the manufacturing process. By implementing magnetic drum separators, businesses can ensure that their final products are free from metallic contaminants, which can otherwise lead to product recalls, damage to machinery, and health hazards for consumers.

Moreover, the efficiency of magnetic drum separators not only protects the product quality but also enhances operational efficiency. By continuously removing metallic debris from the production line, these separators decrease wear and tear on processing equipment, reducing maintenance costs and downtime. This results in a smoother workflow and increased productivity, which are essential for maintaining competitiveness in today’s fast-paced market. Investing in a high-quality magnetic drum separator is a pragmatic choice for businesses aiming to improve their quality control processes and minimize contamination risks effectively.

Cost Savings Achieved Through Effective Metal Separation

Investing in a high-quality magnetic drum separator can lead to significant cost savings for businesses, particularly in industries where metal contamination poses a continual challenge. According to a report by Frost & Sullivan, companies frequently report losses that can exceed 5% of their production yield due to metal contamination, affecting both efficiency and product quality. By implementing effective metal separation technologies, organizations can mitigate these losses, enhancing their overall productivity and bottom line.

Moreover, a study from the National Association of Manufacturers highlights that effective metal separation not only reduces waste and operational costs but also contributes to improved compliance with regulatory standards. When businesses utilize advanced magnetic drum separators, they can minimize the risk of metal-related downtimes and maintenance expenses. As a result, manufacturers can allocate resources more efficiently, ensuring that machinery operates smoothly and maintenance schedules remain on track. The financial benefits extend beyond immediate savings; businesses also improve their reputation and market competitiveness by ensuring product integrity and quality.

5 Compelling Reasons Why the Best Magnetic Drum Separator is Essential for Your Business - Cost Savings Achieved Through Effective Metal Separation

| Reason | Description | Cost Savings (%) | Efficiency Improvement (%) | Return on Investment (Months) |

|---|---|---|---|---|

| Enhanced Metal Recovery | Increases recovery rate of valuable metals from production processes. | 15% | 20% | 6 |

| Reduced Equipment Wear | Prevents metal contaminants from damaging machinery and equipment. | 10% | 25% | 8 |

| Improved Product Quality | Enhances quality of end products by eliminating metal impurities. | 20% | 30% | 5 |

| Compliance with Regulations | Helps meet industry standards for metal contamination levels. | 5% | 15% | 12 |

| Cost Efficiency | Reduces the overall costs associated with waste management and recycling. | 12% | 18% | 7 |

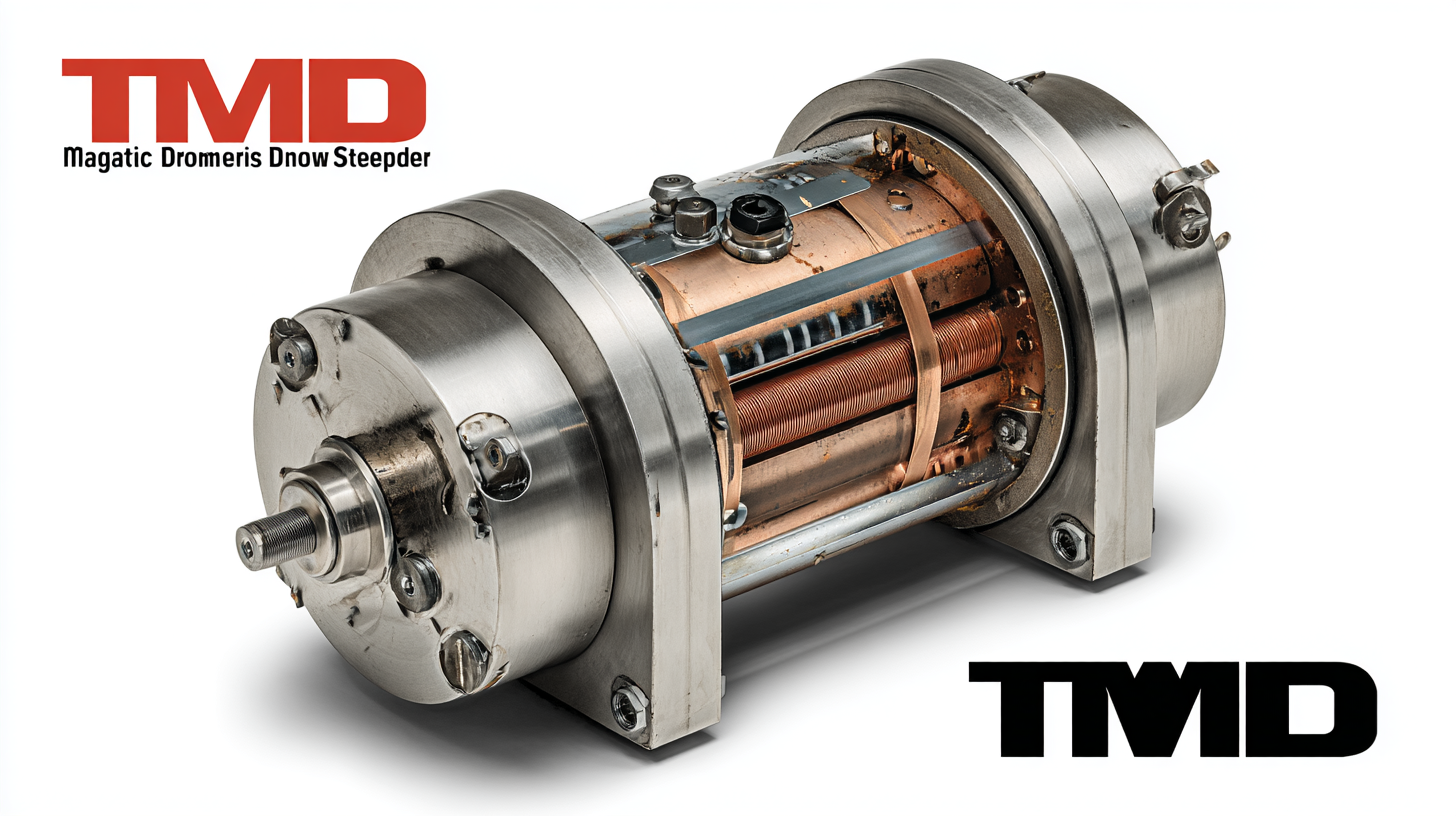

Improving Product Quality with Reliable Magnetic Separation Solutions

Magnetic separation technology has proven to be a game-changer in various industries, particularly in enhancing product quality. By integrating the best magnetic drum separator into your operations, you can effectively eliminate unwanted ferrous contaminants from raw materials. These contaminants can significantly undermine the integrity and quality of your final products. Reliable magnetic separators not only improve product purity but also ensure compliance with regulatory standards, boosting customer confidence and satisfaction.

Furthermore, the use of magnetic separation solutions plays a vital role in maintaining operational efficiency. When ferrous particles are removed from the production line, the risk of equipment damage is minimized, leading to fewer breakdowns and reduced maintenance costs. This not only streamlines production processes but also extends the lifespan of your machinery. Investing in high-quality magnetic drum separators will ultimately result in improved product consistency and a stronger brand reputation, making it an essential asset for any forward-thinking business.

Impact of Magnetic Drum Separators on Product Quality

The Environmental Benefits of Using Magnetic Drum Separators in Manufacturing

The use of magnetic drum separators in manufacturing is not just a trend; it represents a significant advancement toward environmental sustainability. By effectively removing ferrous contaminants from raw materials, these separators ensure that the production process generates minimal waste. This contributes to a cleaner production line and reduces the need for extensive processing, lowering energy consumption and the carbon footprint associated with manufacturing.

Moreover, magnetic drum separators enhance recycling efforts within industries. They can efficiently extract tramp metals and other ferrous materials from recyclable streams, which improves the quality of the end product. This practice not only supports circular economy principles but also promotes responsible waste management, reducing the overall environmental impact. As manufacturers adopt greener technologies and practices, incorporating magnetic drum separators becomes an essential step in aligning business operations with environmental stewardship.